A513 tube baja pasagi pikeun angkutan cairan

A513 Steel Square Tubing, Kandel témbok pipa baja pasagi, diaméterna badag pipa baja pasagi, seamless pipa baja pasagi, alloy low pipa baja pasagi, 135 * 135 * 10 pipa baja pasagi, munara bango pipa baja pasagi, Q345B low alloy pipa baja pasagi, 20 # pipa baja pasagi mulus

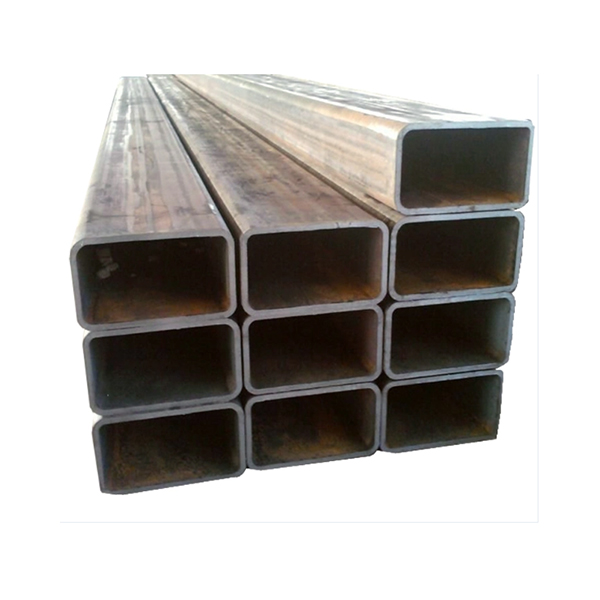

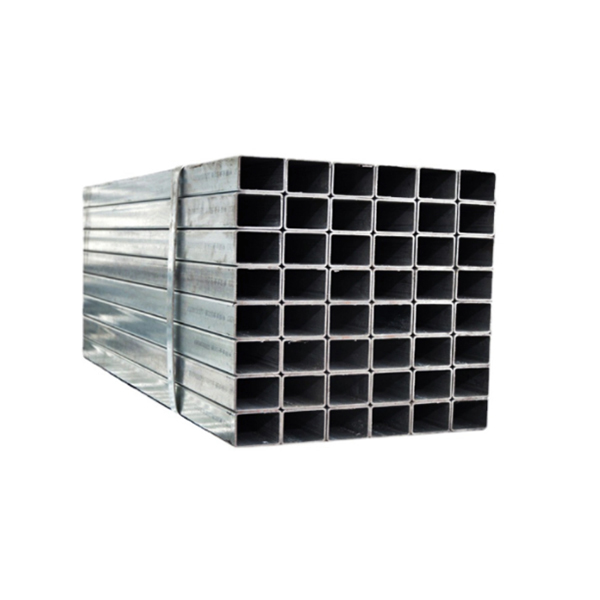

A513 Steel Square Tubing, Sakumaha ngaranna ngakibatkeun, éta bentuk pasagi tina tabung, rupa-rupa bahan bisa ngabentuk awak tube pasagi, sedeng na di, naon make, dimana ngagunakeun, lolobana tube pasagi ka pipe baja. keur mayoritas, lolobana pikeun tube pasagi struktural, hiasan tube pasagi, ngawangun tube pasagi jeung saterusna.

A513 Steel Square Tubing, Ieu ngaran pikeun tube pasagi, nu mangrupakeun tube tina panjangna sarua.Eta dijieunna tina baja strip sanggeus ngolah jeung rolling.Sacara umum, strip ieu unpacked, leveled, crimped na dilas kana tube buleud, nu digulung kana tube pasagi lajeng motong kana panjangna diperlukeun.Biasana 50 batang per bungkus.

A513 Steel Square Tubing, Aya titik seamless na weld, tube pasagi seamless teh seamless tube Tonjolan molding.pipa baja pasagi, témbok kandel pipa baja pasagi, diaméterna badag pipa baja pasagi, seamless pipa baja pasagi, alloy low pipa baja pasagi, 135 * 135 * 10 pipa baja pasagi, munara bango pipa baja pasagi, Q345B low alloy pipa baja pasagi, 20 # pipa baja pasagi mulus

1. Analisis kinerja éksponénsial tina tabung pasagi - plasticity

Plastisitas ngarujuk kana kamampuan bahan logam pikeun ngahasilkeun deformasi plastik (deformasi permanén) tanpa karusakan dina beban.

2. Analisis indéks kinerja tube pasagi - karasa

Teu karasa nyaéta ukuran sabaraha teuas atawa lemes hiji bahan logam.Ayeuna, metodeu anu paling sering dianggo pikeun nangtoskeun karasa dina produksi nyaéta metode karasa indenter, nyaéta ngagunakeun bentuk géométri tina sirah indenter dina beban anu tangtu kana permukaan bahan logam anu diuji, dumasar kana darajatna. indenter pikeun nangtukeun nilai karasa na.

Métode anu biasa dianggo nyaéta Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC) sareng Vickers hardness (HV) sareng metode anu sanés.

3. Analisis indéks kinerja tube pasagi - kacapean

Kakuatan, plastisitas, sareng karasa anu dibahas di luhur mangrupikeun indikator sipat mékanis logam dina beban statik.Nyatana, seueur bagian mesin dioperasikeun dina beban siklik, sareng kacapean tiasa lumangsung dina kaayaan ieu.

4. Analisis indéks kinerja pipa pasagi - dampak kateguhan

Beban anu nimpah bagian-bagian dina laju anu gancang disebut beban dampak, sareng kamampuan logam pikeun nolak karusakan dina beban dampak disebut kateguhan dampak.

5. Analisis indéks kinerja pipa pasagi - kakuatan pipa baja pasagi, témbok kandel pipa baja pasagi, diaméterna badag pipa baja pasagi, seamless pipa baja pasagi, alloy low pipa baja pasagi, 135 * 135 * 10 pipa baja pasagi, munara bango pipa baja pasagi , Q345B low alloy pipa baja pasagi, 20 # pipa baja pasagi seamless

Kakuatan nyaéta kamampuan bahan logam pikeun nolak kagagalan (deformasi palastik kaleuleuwihan atanapi narekahan) dina kaayaan beban statik.Alatan mode of loading dina bentuk manjang, komprési, bending, shearing, jadi kakuatan ogé dibagi kana kakuatan tensile, kakuatan compressive, kakuatan bending, kakuatan geser jeung saterusna.Sering aya sambungan anu tangtu antara rupa-rupa kakuatan, sareng kakuatan tensile umumna dianggo salaku panunjuk kakuatan anu paling dasar.

Ukuran

| Ukuran ku Inci (diaméter) | Kandelna | Ukuran ku MM (diaméterna) | Kandelna |

| inci | inci | mm | mm |

| UKURAN 1/2" x 1/2" | 0,065" | 16mm × 16mm | 0.4mm ~ 1.5mm |

| UKURAN 3/4" x 3/4" | 0,049" | 18mm × 18mm | 0.4mm ~ 1.5mm |

| 0,065" | 20mm × 20mm | 0.4mm ~ 3mm | |

| 0,083" | 22mm × 22mm | 0.4mm ~ 3mm | |

| 0,120" | 25mm × 25mm | 0.6mm ~ 3mm | |

| 1" x 1" | 0,049" | 30mm × 30mm | 0.6mm ~ 4mm |

| 0,058" | 32mm × 32mm | 0.6mm ~ 4mm | |

| 0,065" | 34mm × 34mm | 1 mm ~ 2 mm | |

| 0,072" | 35mm × 35mm | 1 mm ~ 4 mm | |

| 0,083" | 38mm × 38mm | 1 mm ~ 4 mm | |

| 0,095" | 40mm × 40mm | 1mm ~ 4.5mm | |

| 0,109" | 44mm × 44mm | 1mm ~ 4.5mm | |

| 0,120" | 45mm × 45mm | 1 mm ~ 5 mm | |

| 1 1/8" x 1 1/8" | 0,035" | 50mm × 50mm | 1 mm ~ 5 mm |

| 0,049" | 52mm × 52mm | 1 mm ~ 5 mm | |

| 0,065" | 60mm × 60mm | 1 mm ~ 5 mm | |

| 0,109" | 70mm × 70mm | 2mm ~ 6mm | |

| 0,120" | 75mm × 75mm | 2mm ~ 6mm | |

| 1 1/4" x 1 1/4" | 0,049" | 76mm × 76mm | 2mm ~ 6mm |

| 0,065" | 80mm × 80mm | 2mm ~ 8mm | |

| 0,072" | 85mm × 85mm | 2mm ~ 8mm | |

| 0,083" | 90mm × 90mm | 2mm ~ 8mm | |

| 0,109" | 95mm × 95mm | 2mm ~ 8mm | |

| 0,120" | 100mm × 100mm | 2mm ~ 8mm | |

| 0,135" | 120mm × 120mm | 4mm ~ 8mm | |

| 0,156" | 125mm × 125mm | 4mm ~ 8mm | |

| 0,188" | 130mm × 130mm | 4mm ~ 8mm | |

| 1 1/2" x 1 1/2" | 0,049" | 140mm × 140mm | 6mm ~ 10mm |

| 0,065" | 150mm × 150mm | 6mm ~ 10mm | |

| 0,072" | 160mm × 160mm | 6mm ~ 10mm | |

| 0,083" | 180mm × 180mm | 6mm ~ 12mm | |

| 0,109" | 200mm × 200mm | 6mm ~ 30mm | |

| 0,120" | 220mm × 220mm | 6mm ~ 30mm | |

| 0,140" | 250mm × 250mm | 6mm ~ 30mm | |

| 0,188" | 270mm × 270mm | 6mm ~ 30mm | |

| 0,250" | 280mm × 280mm | 6mm ~ 30mm | |

| UKURAN 1 3/4" x 1 3/4" | 0,065" | 300mm × 300mm | 8mm ~ 30mm |

| 0,083" | 320mm × 320mm | 8mm ~ 30mm | |

| 0,095" | 350mm × 350mm | 8mm ~ 30mm | |

| 0,109" | 380mm × 380mm | 8mm ~ 30mm | |

| 0,120" | 400mm × 400mm | 8mm ~ 30mm | |

| 0,188" | 420mm × 420mm | 10mm ~ 30mm | |

| 2" x 2" | 0,049" | 450mm × 450mm | 10mm ~ 30mm |

| 0,065" | 480mm × 480mm | 10mm ~ 30mm | |

| 0,083" | 500mm × 500mm | 10mm ~ 30mm | |

| 0,109" | 550mm × 550mm | 10mm ~ 40mm | |

| 0,120" | 600mm × 600mm | 10mm ~ 40mm | |

| 0,145" | 700mm × 700mm | 10mm ~ 40mm | |

| 0,165" | 800mm × 800mm | 10mm ~ 50mm | |

| 0,188" | 900mm × 900mm | 10mm ~ 50mm | |

| 0,250" | 1000mm × 1000mm | 10mm ~ 50mm | |

| 0,312" | |||

| UKURAN 2 1/4" x 2 1/4" | 0,188" | ||

| 0,250" | |||

| UKURAN 2 1/2" x 2 1/2" | 0,083" | ||

| 0,109" | |||

| 0,120" | |||

| 0,188" | |||

| 0,250" | |||

| 0,312" |

| 3" x 3" | 0,083" |

| 0,120" | |

| 0,188" | |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| UKURAN 3 1/2" x 3 1/2" | 0,120" |

| 0,188" | |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 4" x 4" | 0,083" |

| 0,120" | |

| 0,156" | |

| 0,188" | |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" |

| UKURAN 4 1/2" x 4 1/2" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 5" x 5" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 6" x 6" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 7" x 7" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" |

| 8" x 8" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 9" x 9" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 10" x 10" | 0,188" |

| 0,250" | |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 12" x 12" | 0,250" |

| 0,312" | |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 14" x 14" | 0,312" |

| 0,375" | |

| 0.500" | |

| 0,625" | |

| 16" x 16" | 0,312" |

| 0,375" | |

| 0.500" | |

| 0,625" |

Komposisi Kimia Bahan

| Kelas | unsur | C | Mn | P | S |

| ASTM A500 Gr.b | % | 0,05%-0,23% | 0,3%-0,6% | 0,04% | 0,04% |

| Acc.to EN10027/1 | Acc.to EN10027/2 | C% max (WT Normal (mm) | Si% max | Mn% max | P% max | S% max | N% max | |

| sareng IC 10 | ≤ 40 | |||||||

| S235JRH | 1.0039 | 0.17 | 0.20 | - | 1.40 | 0.045 | 0.045 | 0.009 |

| S275JOH | 1.0149 | 0.20 | 0.22 | - | 1.50 | 0,040 | 0,040 | 0.009 |

| S275J2H | 1.0138 | 0.20 | 0.22 | - | 1.50 | 0.035 | 0.035 | - |

| S355JOH | 1.0547 | 0.22 | 0.22 | 0.55 | 1.60 | 0,040 | 0,040 | 0.009 |

| S355J2H | 1.0576 | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | - |

Sipat Mékanis Bahan

| Kelas | Kakuatan ngahasilkeun | Kakuatan regangan | Elongation |

| A500.Gr.b | 46 ksi | 58 ksi | 23% |

| A513.GR.B | 72 ksi | 87 ksi | 10% |

| norma | Kakuatan ngahasilkeun | Kakuatan regangan | Min.elogation | Min.persen sipat | ||||||||

| Acc.to EN10027/1jeung IC 10 | Acc.to EN10027/2 | Biasa tina WTmm | Biasa tina WTmm | Longit. | Meuntas | Uji suhu °C | Rata-rata nilai dampak min | |||||

| ≤16 | > 6 | >40 | <3 | ≤3≤65 | Biasa tina WTmm | |||||||

| ≤65 | ≤65 | ≤40 | >40 | >40 | ≤65 | |||||||

| ≤65 | ≤40 | |||||||||||

| S253JRH | 1.0039 | 235 | 225 | 215 | 360-510 | 340-470 | 26 | 25 | 24 | 23 | 20 | 27 |

| S275JOH | 1.0149 | 275 | 265 | 255 | 410-580 | 410-560 | 22 | 21 | 20 | 19 | 0 | 27 |

| S275J2H | 1.0138 | 275 | 265 | 255 | 430-560 | 410-560 | 22 | 21 | 20 | 19 | -20 | 27 |

| S355JOH | 1.0547 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | 0 | 27 |

| S355J2H | 1.0576 | 355 | 345 | 335 | 510-680 | 490-630 | 22 | 21 | 20 | 19 | -20 | 27 |

Spésifikasi sarimbag

| EN 10210-1 | NF A 49501 NF A 35501 | DIN 17100 DIN 17123/4/5 | BS 4360 | UNI 7806 |

| S235JRH | E 24-2 | St 37.2 | - | Fe 360 B |

| S275JOH | E 28-3 | St 44.3 U | 43 C | Fe 430 C |

| S275J2H | E 28-4 | Jalan 44.3 N | 43 D | Fe 430 D |

| S355JOH | E 36-3 | St 52.3 U | 50 C | Fe 510 C |

| S355J2H | E 36-4 | Jalan 52.3 N | 50 D | Fe 510 D |

| S275NH | - | Jalan E 285 N | - | - |

| S275NLH | - | TSt E 285 N | 43 EEH | - |

| S355NH | E 355 R | Jalan E 355 N | - | - |

| S355NLH | - | TSt E 355 N | 50 EEH | - |

| S460NH | E 460 R | Jalan E 460 N | - | - |

| S460NLH | - | TSt E 460 N | 55 EEH | - |

- hurup blok "S" hartosna "BAJA UNTUK APLIKASI STRUKTURAL"

- Gambar hareup hartina minim.nilai ngahasilkeun diperlukeun pikeun ketebalan témbok ≤16 mm

- "J2" hartosna nilai uji dampak -20 ° C mnt.27 jol

- hurup blok "H" hartina "BAGIAN HOLLOW".

Pintonan produk