pipa baja komposit Galvanized pikeun suplai cai sarta tarung seuneu jeung plastik

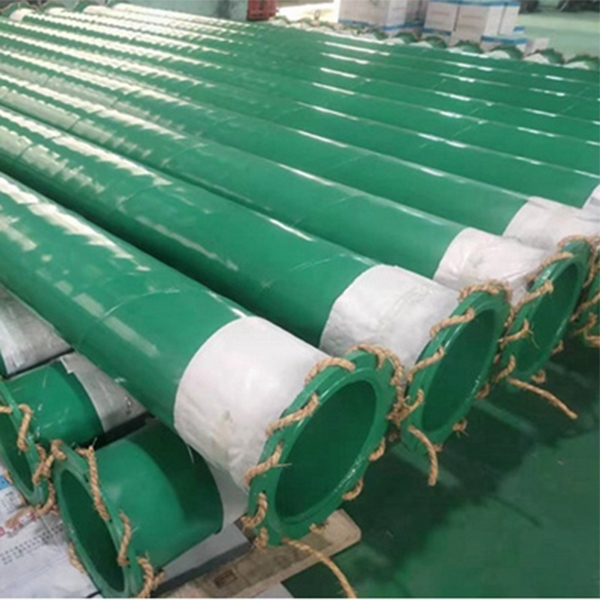

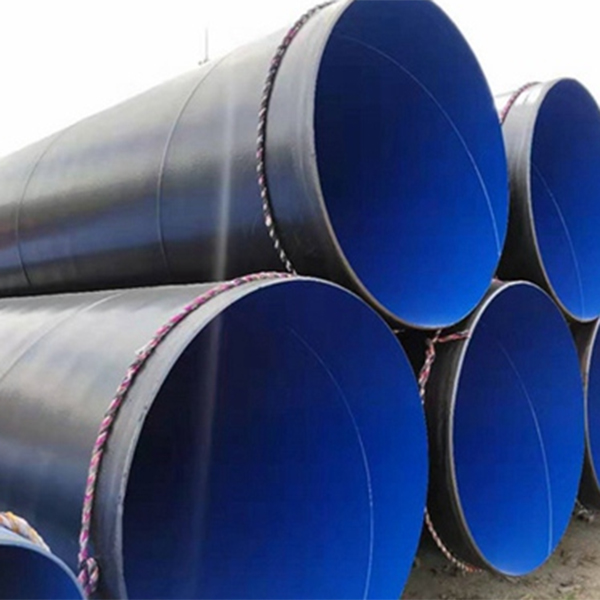

Pipa cai coated palastik, Pikeun résin epoxy dirobah atawa bubuk poliétilén jero sarta luar coated pipe palastik.

Palastik pipa cai coated, Cai mibanda kinerja komprehensif alus teuing jeung lalawanan korosi kuat, pamakéan hawa éksternal -40 ℃ - 90 ℃.Suhu pangiriman cai anu dianggo nyaéta -30 ℃ - 80 ℃.The coated pipe baja palastik pikeun suplai cai téh punjul dina stabilitas kimiawi jeung kinerja Saniter, sarta pinuh conforms kana standar evaluasi kaamanan tina pangiriman cai nginum jeung alat distribusi jeung bahan pelindung.

Pipa Cai dilapis palastik, Fitur Produk

Pasokan cai coated palapis tube baja palastik permukaan lemes, geulis, warna lampu éksternal tiasa pilihan.Alatan témbok jero lemes, bisa nyegah beternak mikroorganisme, résistansi leutik transmisi cairan, bisa ningkatkeun aliran, ngahemat énergi, dipaké pikeun sagala jinis suplai cai sarta rékayasa drainase.

Pipa Cai Dilapis Plastik, Lingkup Aplikasi

Utamana dipaké pikeun pipa suplai cai nginum, sarta seawater, cai reclaimed, kimia jeung minyak bumi, sarta paling asam, alkali, uyah, utamana cocog pikeun pipa dikubur, hirup layanan 50 taun.

Palastik Palapis Cai Pipa, The Performance Index

1, kakuatan komprehensif henteu kirang ti 1.6mpa;

2, dina test bending antara palapis teu layu atawa gugur, fenomena narekahan;

3, dina test flattening antara palapis teu layu atawa gugur, fenomena narekahan;

4, dina uji kinerja kaséhatan, saluyu sareng standar pamariksaan GB / T219-1998;

5, palapis luar conforms kana CJ / T120-2008 baku inspeksi;

6, kakuatan dampak KG / cm> = 50, standar inspeksi conforms kana GB / T1732-1993.

Pipa Cai dilapis palastik, Standar Produk

CJ / T120-2008 "Plastik dilapisan pipa baja komposit pikeun suplai cai"

GB / T17219-1998 Kaséhatan kinerja Indikator standar palaksanaan

Spésifikasi

| Barang | Pipa cai dilapis palastik |

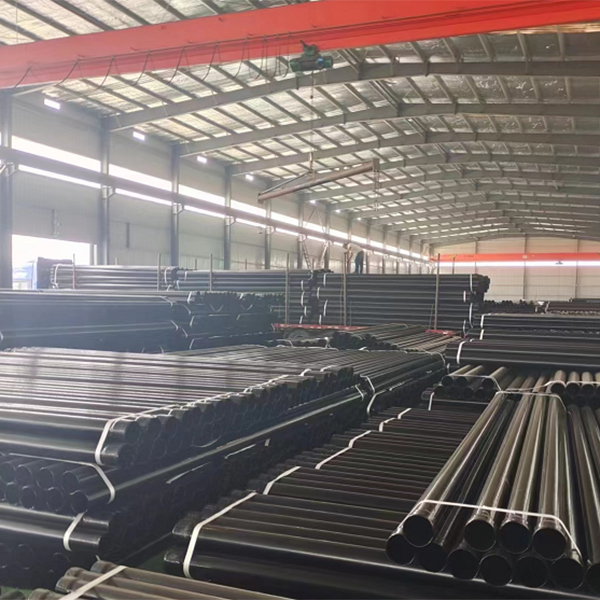

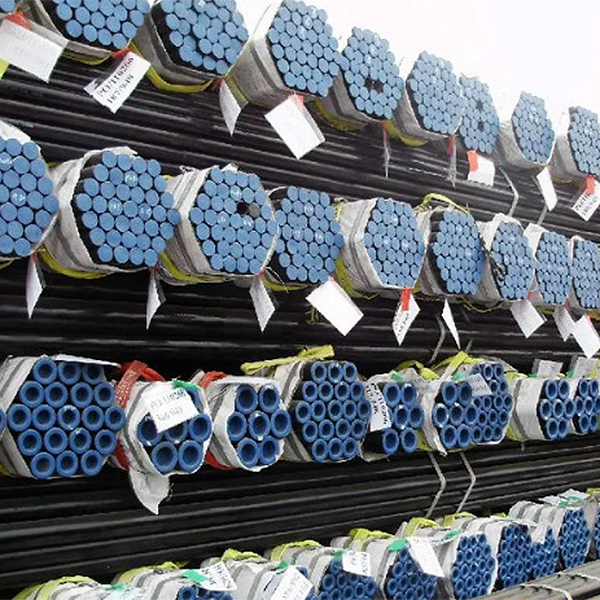

| Bahan | SPHC, Q195,Q215,Q235,Q345,SAE1010,SAE1020, Bahan Standar API, ASTM A53 A,B |

| OD | 10-1219(1/8''-48'') |

| WT | 0.7-13 |

| Panjangna | 2m-12m atanapi sakumaha per sarat konsumén ' |

| Toleransi Ketebalan | + 5%- |

| Beungeut | oiled / dicét |

| Tungtung pipa | tungtung polos / tungtung Beveled / Thread kalawan gandeng jeung cap |

| Nyirian | Salaku per sarat customer urang |

| Sdandard | ASTM / BS EN / DIN / GB |

| Sertipikat | ISO, BV, API |

| ODM / OEM | aya |

| Standar | ASTM A53,BS1387-1985,GB/T3091-2001,GB/T13793-92, GB/T6728-2002 |

| Bahan | Q195, Q215, Q235, Q345 |

| Téhnik | Dilas |

| Pamakéan | Mékanis & Pabrik, Struktur Baja, Ngawangun Kapal, Bridging, Sasis Mobil |

Komposisi kimiawi

| Kelas | C | Mn | Si | S | P | UTS (MPa) | YS (MPa) | EI(%) |

| Q235B | 0.12-0.20 | 0.30-0.70 | 0.30 | 0.045 | 0.045 | 375-500 | 235 | 26 |

| Q345B | 0.12-0.20 | 1.20-1.60 | 0.20-0.55 | ≤0,045 | ≤0,045 | 510-600 | 345 | 22 |

| 20# (GB) | 0.17-0.23 | 0.38-0.65 | 0.17-0.37 | ≤0,030 | ≤0,030 | 410-550 | ≥245 | ≥20 |

| Bagan ukuran pipa HDPE | |||||||||

| Dia | simpangan | 0,4 Mpa | 0,5 Mpa | 0,6 Mpa | 0,8 Mpa | 1.0Mpa | 1.25Mpa | 1.6MPa | 2.0Mpa |

| Kandelna | Kandelna | Kandelna | Kandelna | Kandelna | Kandelna | Kandelna | Kandelna | ||

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm |

| 16 | 0.3 | 2.3 | |||||||

| 20 | 0.3 | 2.3 | 2.3 | ||||||

| 25 | 0.3 | 2.3 | 2.3 | 3 | |||||

| 32 | 0.3 | 2.3 | 2.4 | 3 | 3.6 | ||||

| 40 | 0.4 | 2.3 | 2.4 | 3 | 3.7 | 4.5 | |||

| 50 | 0.4 | 2.3 | 2.4 | 3 | 3.7 | 4.6 | 5.6 | ||

| 63 | 0.4 | 2.5 | 3 | 3.8 | 4.7 | 5.8 | 7.1 | ||

| 75 | 0.5 | 2.9 | 3.6 | 4.5 | 5.6 | 6.8 | 8.4 | ||

| 90 | 0.6 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 | 10.1 | ||

| 110 | 0.7 | 4.2 | 5.3 | 6.6 | 8.1 | 10 | 12.3 | ||

| 125 | 0.8 | 4.8 | 6 | 7.4 | 9.2 | 11.4 | 14 | ||

| 140 | 0.9 | 5.4 | 6.7 | 8.3 | 10.3 | 12.7 | 15.7 | ||

| 160 | 1 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 | 17.9 | ||

| 180 | 1.1 | 6.9 | 8.6 | 10.7 | 13.3 | 16.4 | 20.1 | ||

| 200 | 1.2 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 | 22.4 | ||

| 225 | 1.4 | 8.6 | 10.8 | 13.4 | 16.6 | 16.6 | 25.2 | ||

| 250 | 1.5 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 | 27.9 | ||

| 280 | 1.7 | 10.7 | 13.4 | 16.6 | 20.6 | 25.4 | 31.3 | ||

| 315 | 1.9 | 7.7 | 9.7 | 12.1 | 15 | 18.7 | 23.2 | 28.6 | 35.2 |

| 355 | 2.2 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 | 39.7 |

| 400 | 2.4 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 | 44.7 |

| 450 | 2.7 | 11 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 | 50.3 |

| 500 | 3 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 | 55.8 |

| 560 | 3.4 | 13.7 | 17.2 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 | 62.5 |

| 630 | 3.8 | 15.4 | 19.3 | 24.1 | 30 | 37.4 | 46.3 | 57.2 | 70.3 |

| 710 | 6.4 | 17.4 | 21.8 | 27.2 | 33.9 | 42.1 | 52.2 | 64.5 | 79.3 |

| 800 | 7.2 | 19.6 | 24.5 | 30.6 | 38.1 | 47.4 | 58.8 | 72.6 | 89.3 |

| 900 | 8.1 | 22 | 27.6 | 34.4 | 42.9 | 53.3 | 66.2 | 81.7 | |

| 1000 | 9 | 24.5 | 30.6 | 38.2 | 47.7 | 59.3 | 72.5 | 90.2 | |

Pintonan produk